RIEGER not only manufactures valves, but also complex valve systems and units. This is done in close collaboration with renowned OEMs and plant manufacturers or directly with end customers. These aseptic or hygienic systems are used in plants of the brewery and beverage industry, in dairies and in the food and pharmaceutical industry worldwide.

Upon request, we combine our valves to complete manifold/valve clusters according to customers’ specifications. The execution is carried out in close cooperation and continuous consultation with the engineering department of the customer. We offer support from the PID over 3D-design until on-site installation and after sales service..

A CIP system usually consists of the following assemblies:

Centrifugal pumps

Diaphragm pumps

Connectors:

Now available with TA-Luft certificate

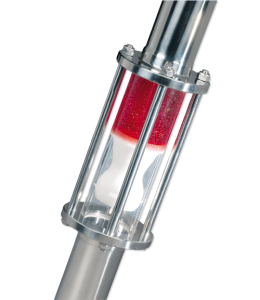

Aseptic pigging station

Modern recovery systems are used for fast, easy and reliable emptying of pipelines. They are also used for the separation of different batches or products within an aseptic production process.

Why aseptic pigging technology?

The investment pays for itself on average after seven months.

Now also available with TA-Luft certificate (Clean Air Act – environmental protection) – for more details CLICK HERE

The straight-way valves D4 (manual version) and D71 (pneumatic version) in hygienic and aseptic design can also be found in our catalogue.

The development of the RIEGER double sealing valve DD to piggable variant N4 allows users great savings in resources. The cost savings of product, water, cleaning agents, environmental pollution recoup the investment within a very short time .

Further information on pig types can be found in the AWH brochure “Hygienic pigging technology“.

Motive medium feed

For secure treatment of sensitive products we offer ready-made modules for driving media feed. The compact module includes all connections for driving/controlling.

For secure treatment of sensitive products we offer ready-made modules for driving media feed. The compact module includes all connections for driving/controlling.