RIEGER hygienic double-seat valves offer reliable protection for your product by separating incompatible products in a leak-proof manner. They have proven themselves for years in plants in the beverage and brewing industry, the pharmaceutical industry as well as the food and dairy industry.

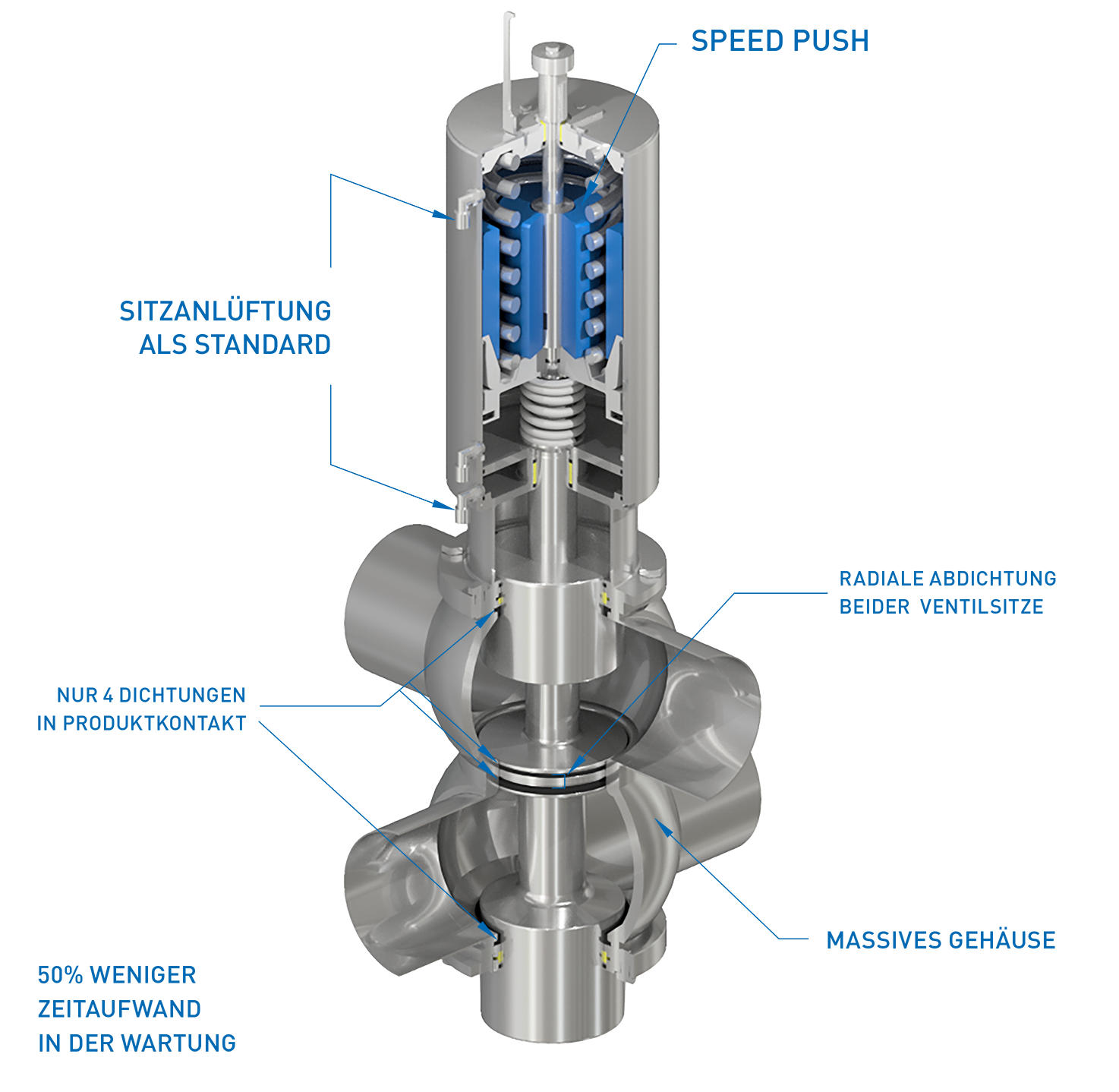

The design of the one-piece solid valve body and the radial sealing of both valve seats together with the balanced valve discs enable completely safe CIP/SIP cleaning and thus ensure extremely high safety for your products.

| SpeedPush drive |  |

| Air consumption and the consumption of cleaning chemicals when using double-seat valves can and should also be taken into account for the total cost of ownership.

To reduce air consumption and the consumption of cleaning media, double-seat valves with reduced air volume in the actuator are recommended. With a reduced air volume, faster switching of the valve discs is possible during CIP to achieve the desired cleaning result even faster. This means that less cleaning media is required throughout the cleaning cycle. |

| Material | in contact with the product optional not in contact with the product |

1.4404/AISI316L 1.4435/AISI316L 1.4301/AISI304 |

|

| Seals | O-rings/seals | EPDM (others on request) |

|

| Temperatures | maximum | EPDM | |

| Continuous operating temperature Sterilization temperature |

130 °C* 150 °C* for a short time (approx. 20 min) |

||

| Press | Closing pressure

Control air pressure |

max. 10 bar

min 6 bar – |

|

| Surfaces | in contact with the product optional not in contact with the product |

Ra ≤ 0.8 µm e-polished, other surfaces on request Ra ≤ 1.6 µm |

|

| Connections Standard- Pipe classes |

DIN 11850-R2 (DIN 11866 A) O.D.-Tube (DIN 11866 C) |

||

|

|

The control head from Rieger was developed in collaboration between AWH and Rieger together with Bürkert.

Rieger thus offers you a tailor-made solution for your in-house hygienic and aseptic process valves, enabling them to be used even more efficiently and accurately.

NON-CONTACT INDUCTIVE VALVE POSITION DETECTION (TEACH FUNCTION)

The FlowStar is available in 24 V DC, AS-I bus, IO-Link (Port Class A) or Ethernet IP versions.

All versions are available as the following alternative:

Mounting kit integrated in the control head – no separate mounting kit required. Exception for LCV valves, ESV valves.

All valves are available in special materials such as Hastelloy® C-22, 1.4539/904L, 1.4529, AL-6XN® and others .

Please contact us directly:

sales@rr-rieger.de

Tel.: +49 7361 5702-0