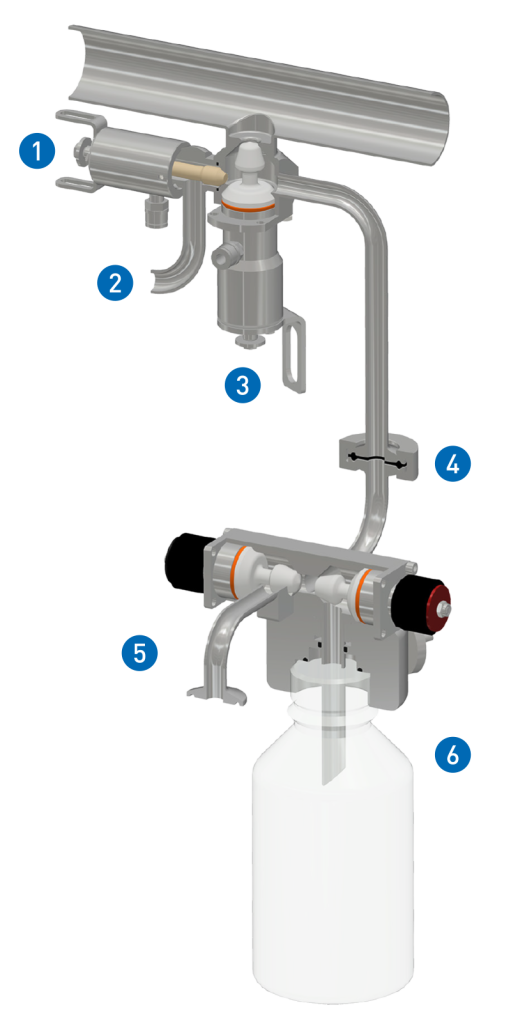

With the BioCheck sampling system, samples can be taken easily and safely from closed systems such as containers and pipes. When designing this sterile fitting, particular emphasis was placed on the aseptic but also very compact design, so that it can be integrated into both sterile and CIP/SIP circuits without any problems and, above all, without contamination.

| Material | in contact with the product optionalnot in contact with the product |

1.4404/AISI316L 1.4435/AISI316L Hastelloy® C-22 and others 1.4301/AISI304 |

|

| Seals | Teflon bellows | PTFE | |

| Temperatures | maximum | PTFE | |

| Continuous operating temperature

Sterilization temperature |

121 °C*

135 °C* for a short time |

||

| Press | Closing pressure | max. 6 bar | |

| Surfaces | in contact with the product optionalnot in contact with the product |

Ra ≤ 0.8 µm e-polished, other surfaces on request Ra ≤ 1.6 µm |

|

| Connections Standard- Pipe classes |

DIN 11850-R2 (DIN 11866 A) O.D.-Tube (DIN 11866 C) |

||

Withdrawal procedure

Withdrawal procedureSterile bottle removal

Not available for this article.

All valves are available in special materials such as Hastelloy® C-22, 1.4539/904L, 1.4529, AL-6XN® and others .

Please contact us directly:

sales@rr-rieger.de

Tel.: +49 7361 5702-0